Lycoming O-145-B2

The Lycoming Model O-145 engines are four cylinder, horizontally opposed, air-cooled aircraft engines. The A, B, and C series are identical in design with only such changes in construction as to permit the different horsepower ratings. The O-145 is direct drive while the GO-145 has a reduction gearing ratio of 27 to 17. The piston displacement for all models is 144.5 cubic inches. The A series is rated at 50-55 HP at 2300 RPM, the B series at 65 HP at 2550 RPM, and C series at 75 HP at 3100 RPM. The G series is 75 HP at 3200 RPM with a propeller RPM of 2015. The number following the letter denotes the equipment on the engine. 1 is single ignition, 2 is dual ignition, and 3 is dual ignition with generator and starter drives.

Ready to dissamble

Magnetos off

Carburetor and oil sump removed

Top cover and accessory case removed

Cylinder heads removed

Loose valve seat is the reason it wasn’t running right

All the parts cleaned and ready to go back together

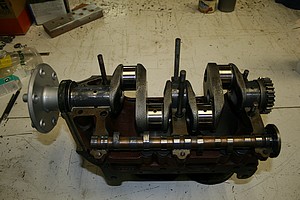

Camshaft and crankshaft in place

Crankcase halves bolted together

Bottom side showing the camshaft

Crank and cam gears installed

Back case in stalled

Pistons and connecting rods going together

All the pistons are in and waiting for the top cover

Ready to install cylinder heads

Cylinder head parts

First head installed

All the cylinder heads are on

Valves adjusted, covers and spark plugs installed

Magnetos installed

In the aeroplane and test run